SMART FACTORY

スマートファクトリー

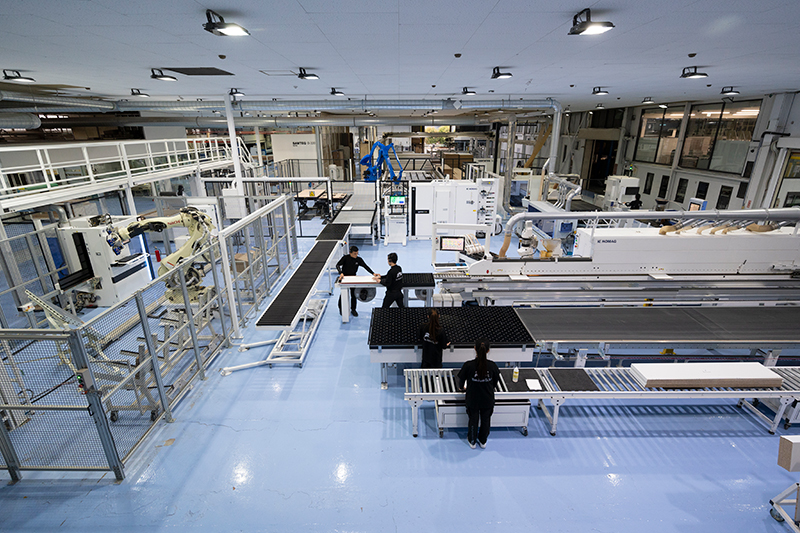

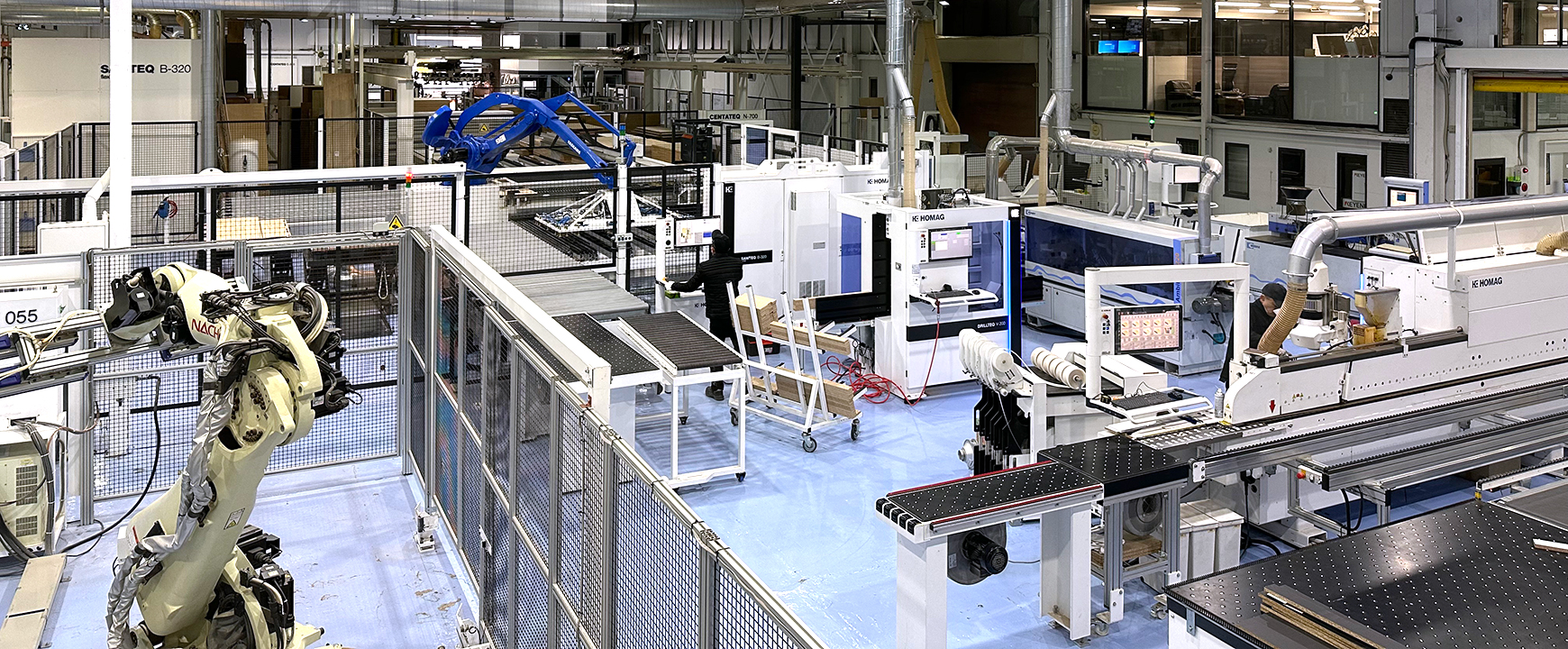

スマートファクトリーの導入

当社の日本およびベトナムの設備はほとんどがHOMAG社製であり、全ての設備がネットワークで接続されています。製品はデジタルデータ内で完成させ、その完成したデータから加工機が作業を行います。人は「人にしかできない」作業のみを行います。

あらゆる工程をデジタル化することで、設備の潜在能力を最大限に引き出します。これからはますます多様化する需要に応えるため、「製造プロセスのデジタル化」を推進して参ります。

ORDER MADE

オーダーメイド

様々な形状加工に対応

当社はこれまで製造のデジタル化を進めてまいりました。これにより、デザインやサイズ仕様の異なる単品オーダーを大量に生産することが可能となりました。第一に、製品をデータ内で完成させます。

ネットワーク内のデジタル加工機が複数の加工を複数の機械で行います。すべてがバーコードで管理され、誤りのない製品が完成します。安定した品質、安定した価格、そして安定した納期をお客様のニーズに合わせてご提案することが可能です。

▶ IMOS社ホームページで当社が事例で紹介されています。

PAINTING

木製品の塗装にも対応

加工から塗装まで一貫生産

最新鋭の自動塗装機(1基)と4メートルのブース(6基)の設備を備えており、木製品の塗装において優れた技術を有しています。目的に応じて自動塗装機と手作業による塗装を切り替え、多くのブースを使用することで、多様な塗装に対応することが可能です。また、加工から塗装まで一貫した生産を行うことで、全ての製品に対して責任を持って対応できます。

ORDER SYSTEM

万全の受注体制

独自の生産管理基幹システム

生産管理の基幹システムを独自に構築し、日々システムの改良に取り組むことで、あらゆるニーズに応えられるよう努めています。当社で生産される製品は、それぞれの管理ナンバーによって管理されており、仕掛中であっても出荷済みであっても、生産をトレースすることが可能です(国内・海外工場とも同一システムを使用)。また、基幹システムは独自に構築されており、お客様のニーズに合わせた運用が可能です。

EN

EN VN

VN