Please visit inside our main headquarters factory in Kakamigahara via Google Street View (indoor version).

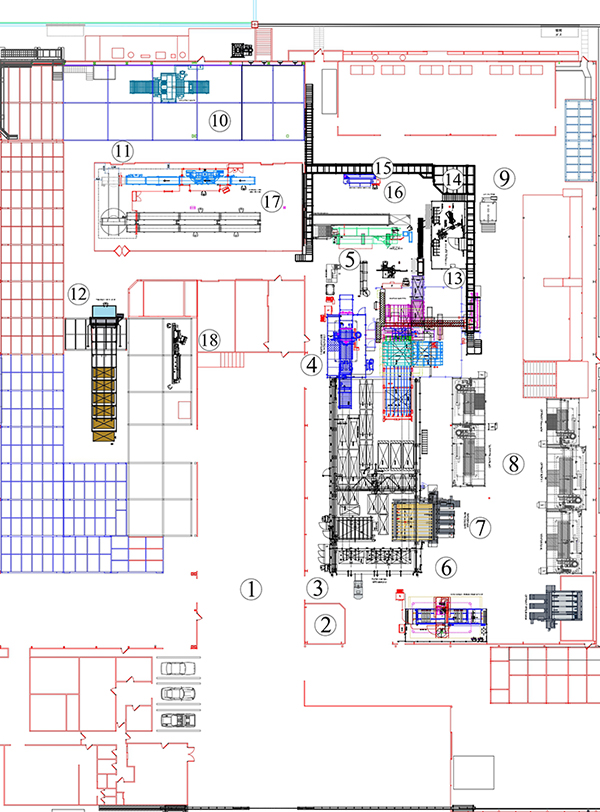

① Entrance

Inside the factory

② Customer support department

Explanation of HOSO’s production process. Products are completed as digital data, and the processing machine will handle the completed data. Only tasks that humans can do are performed.

③ Automated warehouse

Not just a warehouse but also an integral part of the production process. We optimize the production process and reduce all types of waste, including basic raw material inventory management, basic raw material productivity management, process productivity management, and scrap material management.

④ Blanking machine

This blanking machine can simultaneously process parts of different shapes using NC processing from a single original plate. No matter how complex the shape, it can be efficiently and quickly processed.

⑤ Edge banding machine and dowel insertion machine

Parts from the blanking machine will undergo the next process right on the spot. The post-processing is completed based on information from the QR code affixed inside the automated warehouse.

⑥ 5-axis CNC edge banding machine

This 5-axis CNC machine has edge banding functions. It can handle up to 6 meters and can perform NC processing and edge banding on large products and products with curves that cannot be processed by conventional edge banding machines.

⑦ Cutting machine

Based on productivity calculations, QR codes are attached to the materials, which are then sent to the cutting machine. Workers cut the items according to instructions from the machine. If small scraps are found, they are labeled and stored. On the other hand, if there are large scraps, they are returned to automatic warehouse management. Moreover, the processed scrap is incorporated into the next production plan and given priority for use, ensuring efficient resource utilization. This way, we minimize waste of excess raw materials and create an environmentally friendly production system.

⑧ Surface range processing

Processing panel goods using a 5-axis CNC machine. Our products range from rubberwood goods, melamine laminated goods to artificial stone goods. Additionally, there are products made from a single component and products created by combining multiple components, each managed as a separate part. Products with multiple components are assembled during the final processing to create a complete product. All parts are managed by QR codes and processed separately. These are the basic rules in our production process.

⑨ Sanding machine

Equipped with 4 axes, this sanding machine can handle everything from cutting to surface finishing in one go. We also perform various processes, including smoothing primer layers to serve the main painting process.

⑩ Automatic paint spraying machine

This paint sprayer can handle objects of various shapes. The scanner accurately identifies the shape of the item and uses that information to apply optimal coating, making paint usage more efficient and significantly reducing waste. Previous painting work required a lot of manual labor, but now it can be easily and efficiently done with just this machine.

⑪ Visual display of processes

Our employees work together throughout the entire process and always strive to coordinate according to the production plan. You can check the progress of each process anytime.

⑫ Cardboard box cutting machine

Our company handles various types of products and custom-made products, and because the shape and size of the packaging vary depending on the product, we have imported a cardboard cutting machine. This machine allows timely delivery and significantly improves the efficiency of packaging operations. All our packaging work is done by people with disabilities, and with the advent of this machine, we can now provide them with an easier working environment. Thanks to this machine, the speed of work has also been improved.

⑬ High-speed automatic cutting machine

We cut basic cabinet materials from various panel goods, the first of which is rubberwood. After cutting the materials, they are palletized and sent to the next process, as well as continuously transferred to processes such as edge banding, CNC machining, and joint processing. QR labels attached to the materials play a crucial role, allowing the next process operator to work accurately and quickly.

⑭ Factory tour

Please visit our cabinet production site. We are working to establish a system that allows batch production of individual items.

⑮ Edge banding machine

After being sent from the robot arm, the materials are edge-banded. We have created an environment where you can work alone. We are striving to create a post-processing system suitable for the speed of the high-speed cutting machine.

⑯ Connection processing machine

Necessary processing for assembly. This device has CNC functions not only for processing dowels but also for processing various joints.

⑰ Frame assembly machine

Even individual products can be neatly assembled without any special setup. The size is scanned every time it is loaded, so no setup is required. Individual items can be mass-produced.

⑱ Office

We receive orders from customers in various ways, including data, email, PDF, and fax. Similarly ordered forms are temporarily collected in an order folder. Then, our staff at the CAD center in Hue, Vietnam, manually enters this information into the system and digitizes it. Production can only be done after this process. This process is essential for operations in Japan, where the digitization process tends to be slow.

EN

EN VN

VN